Super User

Abril 2015

La medición de la temperatura de las partículas en el interior de los reactores termoquímicos es de suma importancia, debido a que con ello se determina las cinéticas de las reacciones. Sin embargo, debido a la presencia de los flujos de radiación concentrada, dicha medición se complica si esta se realiza a través de técnicas de pirómetro. Por ello, se realizó una campaña experimental para determinar en qué porcentaje se sobrestima la temperatura con pirómetro con presencia de radiación concentrada reflejada por las partículas.

CEToC

Equipos

Internos

Manual de Operación de Sistema de Control de Campo Experimental de Torre Central (CEToC)

Campo Experimental de Torre Central Reglamento de Seguridad

Manual de operación de la estación solarimétrica

Plan de mantenimiento del Campo Experimental de Torre Central

HoSIER

Equipos

Analizadores

Cámara Termográfica

Internos

Abstract

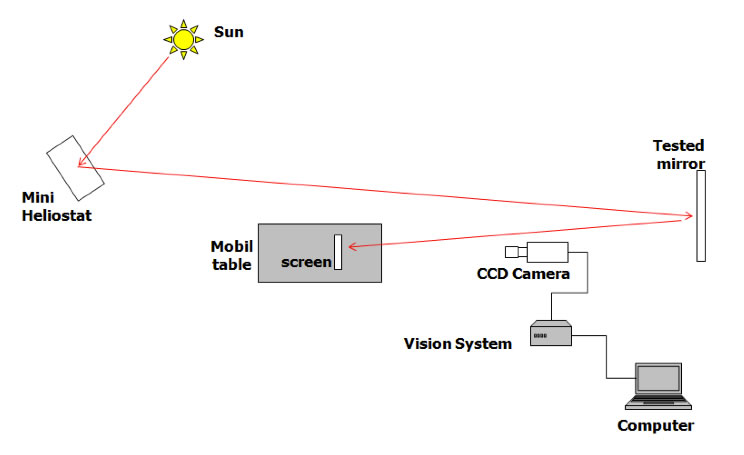

We present the initial results for the comparative study of two types of reflecting surfaces for solar concentrating systems. We use two identical mirrors with different coatings: The first have an aluminium coating with SIO2 protection and the second was covered with the commercial film Reflectech®. This cover is used mainly for parabolic trough and has several advantages like a high reflectivity, low maintenance, and resistance to extreme weather conditions. Since this film was developed for concentrating solar applications, the purpose of this study is exploring the potential application of the film in point focus concentrating systems.

Evaluation of two reflective Coatings for the Mirrors of The High Radiative-Flux Solar Furnace

Riveros-Rosas, R. Castrejón-García, C.A. Arancibia-Bulnes, C.A. Pérez-Rábago, C.A. Estrada

Abstract

The paper presents the technical modifications of DEFRAC (Spanish acronym for Device for the Study of Highly Concentrated Radiative Fluxes) in order to obtain a mini-solar furnace (MSF). DEFRAC is placed in vertical position and the optical arrangement of facets is oriented viewing to the north. A small flat heliostat system with 5.6 m2 of surface area was designed and constructed to track the movement of the sun and redirect sunlight along to the optical axis of the fixed DEFRAC the concentrator. The reflective surface of the heliostat is obtained by using a flat mirror with a tolerance lesser than 1 mrad. The MSF has a shutter with an area of 2.56 m2 that attenuates the solar energy reflected by the heliostat. In this paper we present the preliminary result of the optical performance for the MSF and the evaluation of the track system of the heliostat and the control of the shutter. The MSF will be used in the development of different kind of studies; from studies of heat transfer in open small cavities to the development of small receivers.

Mini-Solar Furnace by Using a Point Focus Solar Concentrator

Pérez-Rábago C.A., D. Riverso-Rosas, O.A. Jaramillo, M. Bazán, M. Carrillo-Santana, M. Montiel-González, G. Ascanio, C.A. Estrada

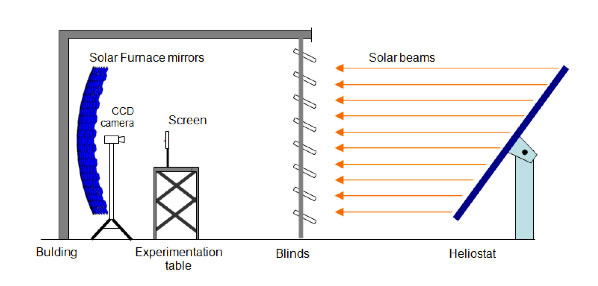

Abstract

In the present work, the analysis of the first images obtained from de Solar Furnace of High Radiative Flux in Mexico is presented. The solar furnace has five different focal distance groups. The images were acquired using the first two groups of mirrors from complete optics of main concentrator. We used a Heliostat with a reflective surface of 36 m². The Images was captured with a CCD camera and the irradiance profile was modeled with a ray-tracing program in order to estimate the global optical error for the concentrator-heliostat optical system. The results shows that the optical error is less to 3 mrad and the calculations indicates that the flux peak for the complete groups of mirrors could be higher than 12 000 suns and the average flux could be higher than 5,000 suns.

David Riveros-Rosas, Carlos A. Perez-Rabago, Camilo A. Arancibia-Bulnes, Ricardo Perez-Enciso, and Claudio A. Estrada

Abstract

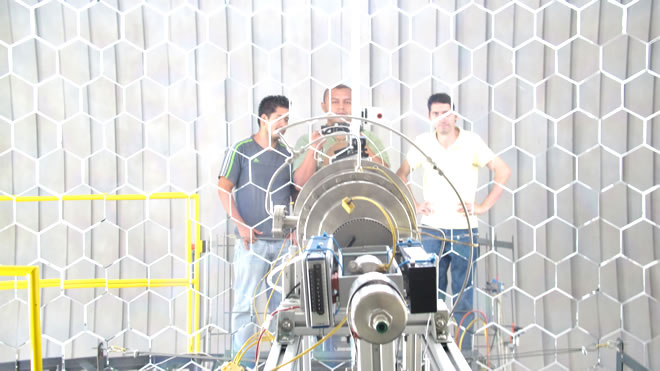

A new high flux solar furnace facility has been developed in Mexico. It is located in Temixco, Morelos, Mexico and in its first phase of development consists of a heliostat of 36 square meters (6 m by 6 m), a shutter made of stainless steel blades 6.2 m by 6.2 m, and a multifaceted concentrator of 211 spherical mirrors with an equivalent focal length of 3.64 m. In order to set the HFSF in operation, all the mirrors were aligned, the control system was developed and tested, the heliostat was aligned and its tracking movement tested. The purpose of this paper is to present the new facility and its first results in the evaluation of its capacities. The results show that the optical error is less to 3 mrad and the calculations indicates that the average flux could be higher than 5,000 suns and the facility can reach temperatures as high as 3406º C.

A New High-Flux Solar Furnace at CIE-UNAM in Temixco, México. First Stage

Claudio A. Estrada, Camilo A. Arancibia-Bulnes, Sergio Vazquez, Carlos A. Pérez-Rábago, David Riveros, Ricardo Perez-Enciso, Jesús Quiñones, Rafael Castrejón, Moises Montiel, Fermín Granados

Abstract

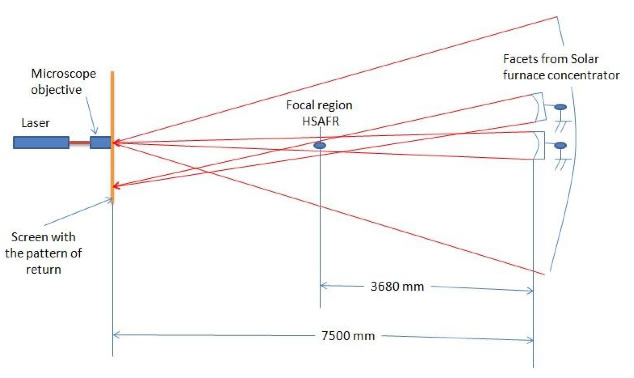

The new high radiative flux solar furnace is being developed in Mexico at the Centro de Investigación en Energía of the Universidad Nacional Autónoma de México. The alignment of the facets of the concentrator is a key procedure to obtain the required energy distribution in the focal zone and to keep the global standard deviation of the optical errors low. We present a novel method for optical alignment of the facets; this alignment procedure requires a simple optical system, allows rapid alignment and guarantees the required accuracy. Preliminary results obtained with this procedure are discussed, which show that the facets alignment satisfactorily meets specifications.

S. Vazquez-Montiel, C.A. Pérez-Rábago, R. Pérez-Enciso, D. Riveros-Rosas, F. Granados-Agustin, C.A. Arancibia-Bulnes, C.A. Estrada