Super User

Martha Escobar-Toledo, Camilo A. Arancibia-Bulnes, Cuitlahuac Iriarte-Cornejo, Julio Waissman, David Riveros-Rosas , Rafael E. Cabanillas and Claudio A. Estrada.

Abstract

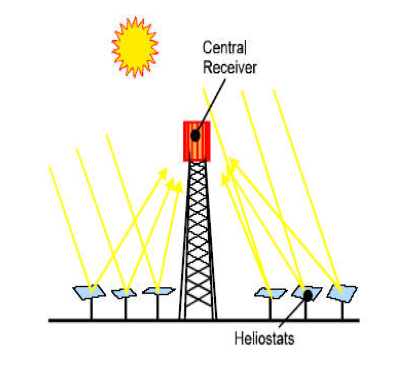

Drift is ubiquitous in heliostat fields, and may be caused by diverse geometrical inaccuracies during heliostat installation and operation. This phenomenon is studied for three important primary errors in the present paper: Angular offset in the drive mechanism, pedestal tilt, and canting error. Each error produces characteristic signatures, but there is a diversity of behavior depending on the error parameters and location of the heliostat. The variation of the extent of drift curves is studied as a function of distance, for fixed error parameters. It is found that, in general, this extent is not proportional to distance, except for far heliostats, and depends on a complicated manner on the different parameters involved. Moreover, even though the extent of drift curves becomes proportional to distance for far heliostats, the convergence is very slow, and very variable with the error parameters.

C. Iriarte-Cornejo, C.A. Arancibia-Bulnes, I. Salgado-Transito, J. Waissman, R.E. Cabanillas, C.A. Estrada.

Abstract

Heliostat image drift is a common phenomenon in central receiver solar power plants. Several geometrical errors produce drift of the heliostat solar spot at receiver surface, increasing radiation spillage. A heuristic drift compensation method is proposed, based on a polynomial approximation to the drift trajectories. Results of the practical implementation of the proposed method for the control of 10 heliostats in a solar tower facility are presented. A substantial improvement of heliostat tracking is observed on the experimental tests. Because heliostat drift experimental monitoring is a time consuming task, a numerical analysis of the yearly behavior of the compensation method, based on simulations of heliostat drift, was carried out. In these simulations, the behavior of the daily RMS deviation of the concentrated solar spot centroid is evaluated for a whole year, as the polynomial correction is applied. The simulations serve also to test the effectiveness of the proposal polynomial method in a wider range of conditions. Thus, heliostats with a variety of primary error values are simulated. Random wind induced vibrations are introduced in the simulation to evaluate the effectiveness of the calibration method under noise conditions. It is found that a very effective calibration can be achieved with a few sampling events of the heliostat behavior during the year, taking only a few minutes. The RMS deviation can be reduced to values of the order of the wind induced noise level. The proposed polynomial compensation looks like a promising alternative to be implemented in heliostat fields.Manuel I. Peña-Cruz, Camilo A. Arancibia-Bulnes, Ana Monreal Vidal, and Marcelino Sánchez González.

Abstract

An improved tool for the shape qualification of parabolic trough mirror modules used in concentrated solar power plants was developed. The tool is based on the fringe reflection theory, in which sinusoidal fringe patterns are projected on a screen and their reflection over a specular surface is recorded by a camera. The observed distortions in the image are related directly to surface deviations from ideal geometry. Relevant aspects of the technique are its high spatial resolution (more than 1 × 106 points per mirror facet), short measurement time and easy setup. The developed tool (called FOCuS) is capable of calculating the local mirror slope deviations from its ideal design and the RMS value as a quality factor. Furthermore, the tool generates a file which can be loaded into CENER's TONATIUH ray tracing software, through a specially developed plug-in, for mirror modeling and intercept factor calculation with several tube absorber geometries.

Improving parabolic trough mirror module qualification by FOCuS tool

Abstract

A 1 kWth cavity-type solar reactor devoted to the thermal reduction of volatile oxides as part of a two-step thermochemical cycle is analyzed numerically. The thermochemical reactor consists of a vertical-axis cavity-type receiver in which the reactant is injected from the bottom in the form of an ascending rod made of a stack of zinc oxide compressed pellets undergoing thermal dissociation. A transient heat transfer model allows the simulation of the thermal behavior under real conditions for the rod of reacting particles exposed to concentrated solar radiation. The developed numerical model couples radiation, conduction and convection heat transfers to the kinetic of the reaction. The incident solar irradiation on the reactant surface is obtained using the Monte-Carlo ray tracing technique applied first to the solar concentrator and second to the reactor cavity. The model is used to predict the temperature profile from the irradiated front surface of the compressed reactant, the evolution of outlet oxygen molar flow-rate during the reduction reaction and the instantaneous thermochemical efficiency, as a function of time. The calculated results are compared with the experimentally obtained data. The agreement between experimental data and simulation related to both the temperature and the oxygen progress is fairly good with Ea = 380 kJ mol−1 and k0 = 246 × 106 mol m−2 s−1 for the kinetics of the ZnO dissociation reaction.

H.I. Villafán-Vidales, S. Abanades, M. Montiel-González, H. Romero-Paredes, C.A. Arancibia-Bulnes, C.A. Estrada, Chemical Engineering Research and Design

R. Pérez-Enciso, E. Brito-Bazan, C.A. Pérez-Rábago, C.A. Arancibia-Bulnes, D. Riveros-Rosas, C.A. Estrada.

Abstract

This paper discusses the methods implemented for the solution of the drift and backlash problems in the heliostat of the High Radiative Flux Solar Furnace recently built at the Renewable Energy Institute (former Center for Energy Research) of the National University of Mexico (IER-UNAM), located at the geographical coordinates 18°50′24″ North latitude and 99°15′00″ West longitude. To solve the observed drift, several algorithms were analyzed for the calculation of the solar vector, and a closed loop through an electronic device (peephole) was implemented which makes corrections to the position of the heliostat. Using the peephole, drift heliostat decreased significantly; 70% in the horizontal direction and 63% in the vertical direction relative to the no use of peephole. The backlash was corrected by means of unbalancing the heliostat.

Correction of the concentrated sunlight spot´s drift of the IER-UNAM´s solar furnace

Elisa Alonso, Carlos Pérez-Rábago, Javier Licurgo, Edward Fuentealba, Claudio A. Estrada.

Abstract

Thermochemical redox processes are currently considered one of the most promising methods for thermal storage of solar energy. Among the different types of materials available for this purpose, metal oxides allow higher operation temperatures in CSP systems. This is in agreement with the new R&D trends that focus on increasing the temperature to augment the efficiency. Copper oxide was previously proposed as a valid metal oxide for thermochemical storage. However, no demonstrative experiments had been carried out so far under solar radiation. In this work, the suitability of copper oxide was proved in a solar furnace. The employed solar reactor was a rotary kiln device with direct radiation absorption on reactive particles, which is a configuration that guarantees higher operation temperatures than other types of solar reactors. Given results include the performance of the CuO reduction in the rotary kiln under argon atmosphere and the cyclability of the pair CuO/Cu2O in air.

L.G. Ceballos-Mendivil, R.E. Cabanillas-López, J.C. Tánori-Córdova, R. Murrieta-Yescas, C.A. Pérez-Rábago, H.I. Villafán-Vidales, C.A. Arancibia-Bulnes, C.A. Estrada.

Abstract

Silicon carbide (SiC) has been prepared successfully using concentrated solar energy provided by the IER-UNAM solar furnace. This has led to the development of a low CO2 emissions process for the production of this material via carbothermic reduction of a silica/carbon (SiO2/C) nanocomposite, which has shown a more reactive carbon for formation of composite, being more thermally stable. Silica (obtained by a sol–gel process) and sucrose were used as precursors of silicon and carbon, respectively, at a temperature of 700 °C in controlled atmosphere (nitrogen) for the formation of the SiO2/C composite. This composite was used in a second step to obtain SiC at a temperature of 1500 °C, in argon atmosphere. The experimental setup used a Pyrex® glass spherical vessel designed to work with concentrated solar power and controlled atmospheres. The structure and morphology of the solar obtained SiC were analyzed with FTIR, XRD, TGA/DSC, SEM and TEM techniques. Results show that it is feasible to use concentrated solar energy for the synthesis of SiC. The solar SiC obtained is nanostructured and is mainly β-SiC.

Synthesis of silicon carbide using concentrated solar energy

Introducción

Para el uso de la energía solar en la Tierra se han creado en general, dos tipos de tecnologías, a saber, las tecnologías de conversión fotovoltaica y las de conversión fototérmica. Los colectores solares fototérmicos son una clase de intercambiadores de calor que transforman la energía solar en energía térmica. En ellos la transferencia de energía es desde una fuente distante de energía radiante (el sol) a un fluido. Sin concentración óptica, el flujo de la radiación solar incidente es, en el mejor de los casos, aproximadamente de 1100 W/m2. Con estos flujos radiativos, se pueden diseñar colectores solares planos para aplicaciones que utilizan temperaturas del fluido hasta de 100 C arriba de la temperatura ambiente. Sin embargo existen muchas otras aplicaciones donde se requieren temperaturas mayores a las normalmente alcanzadas por los colectores planos. Estas temperaturas mayores se pueden conseguir interponiendo un dispositivo óptico entre el sol y la superficie absorbedora de energía, con el objetivo de aumentar la densidad de flujo radiativo incidente en el absorbedor. Estos dispositivos (sistema óptico y absorbedor) se denominan concentradores solares.

De acuerdo con el rango de temperaturas de operación, se pueden mencionar entre las aplicaciones más importantes donde se usan sistemas fototérmicos, las siguientes:

Basten estos ejemplos para observar la variedad de aplicaciones donde los colectores solares de concentración son requeridos.

Tecnología Termosolar SCP

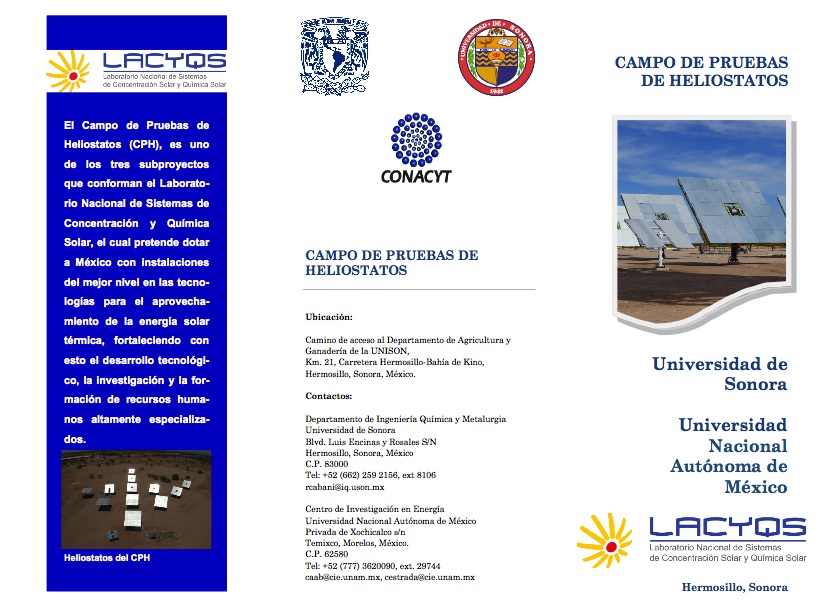

En esta página encontrarás una breve descripción de las tecnologías de concentración para el aprovechamiento de la energía solar fototérmica. Es decir, tecnologías que concentran la radiación solar para su aprovechamiento en procesos térmicos de alta temperatura. También encontrarás información de las principales instituciones en México que desarrollan estas tecnologías, los grupos de investigación y proyectos importantes que se están realizando en el país en tecnologías de concentración solar.

Tipos de Tecnologías

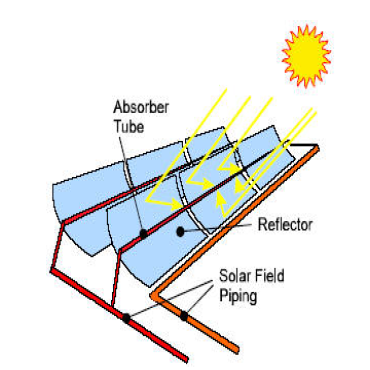

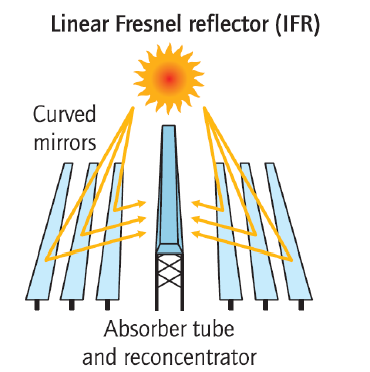

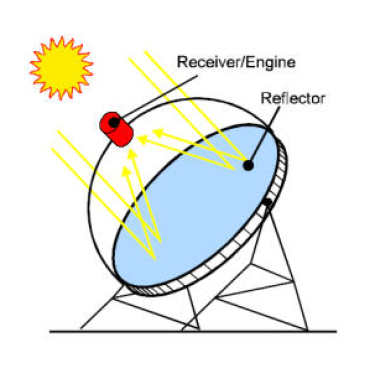

Existen diversos tipos de tecnologías que concentran la radiación solar y su diseño dependen tanto de los procesos ópticos para la captación de energía como del uso final del calor obtenido. La finalidad es incrementar el flujo de radiación solar, sobre receptores diseñados para absorberla. El calor pasa a un fluido térmico (agua, aire, aceite sales fundidas) para alcanzar temperaturas entre los 250°C y 2000°C. Las aplicaciones típicas de estas tecnologías son la producción de electricidad con energía solar. Para ello suele acoplarse, en la región focal, un mecanismo basado en ciclos termodinámicos, o algunos procesos de química solar (por ejemplo el reformado de metano para producir hidrógeno). En esta sección se describen brevemente las tecnologías, las cuales se clasifican en los 3 siguientes grupos:

|

|