Mostrando artículos por etiqueta: SolarPaces Symposium

Experimental analysis of a flat plate receiver for measurement of low thermal power of a central tower solar system

A Piña-Ortiz, JF Hinojosa, RA Perez-Enciso, VM Maytorena, C Estrada, CA Pérez-Rábago, RA Calleja

Abstract

In the city of Hermosillo, in the northwestern state of Sonora, México, the University of Sonora in agreement with the National Autonomous University of México is developing solar tower technology. A thermal receiver was designed to measure the thermal power of a small number of heliostats and experimental results were obtained to measure the thermal power of a small number of heliostats. The flat plate thermal receiver is a parallelepiped enclosure 1.20 m high, 1.23 m wide and 0.1 m deep with a receiving area of 1.476 m2 and a ε = 0.95, It also has 1228 cylindrical fins evenly distributed in the interior, each fin has a diameter of 0.0095 m and a length of 0.09 m, which increases the area of the receiving wall by up to 329%. Three experiments (with 1, 4 and 7 heliostats respectively) were carried out using the effect of the radiative flux provided on: the estimated thermal power, thermal efficiency, temperature distribution of the internal surface of the receiving wall (plate), the temperature distribution in the fins and in the fluid; all of this during steady state conditions. The experiments were performed for a Re⎯⎯⎯⎯ number of 2.90 × 104; it was found that the thermal efficiency of the system decreases as the radiative flux increases. The maximum efficiency was 84.9% and the minimum was 58.4% for experiment 1 and 3 respectively. We also observe that the temperature gradients of the fins increase as the radiative flux increases and that the fluid increases its temperature as it passes through the receiver and the center of the plate has the higher temperatures.

Thermal Behavior and Heat-Flux Distribution in a Solar Rotary Kiln

Alessandro Gallo, Héctor González-Camarillo, María Isabel Roldán, Elisa Alonso, Carlos Pérez-Rábago

Abstract

In this work, the first stage of a project devoted to the evaluation of rotary kilns as thermal receivers for industrialheat production was carried out. A small-scale rotary kiln was designed, installed and tested in the IER-UNAM’s solar furnace. In the experiment, the kiln was filled with 40 g of 2-mm diameter spherical particles and it rotated at 5 rpm. The thermal equilibrium was reached after almost 2 hours of operation and a temperature of 830 ºC was achieved. In order to evaluate the irradiance distribution on the kiln aperture, an indirect estimation method was adopted. The method consists in determining firstly the Solar Furnace Factor and the incident power, and then it is calibrated the image of the irradiance distribution on a Lambertian target placed at the furnace focus. This method does not require any measurement of the irradiance on the target plane. Once the irradiance distribution was calibrated, it was compared with a ray-tracing simulated irradiance of the same system at the selected position, obtaining a maximum average deviation of 2.8%. Furthermore, a parametric analysis of the internal wall absorptance and kiln position was carried out in order to evaluate the heat-flux distribution on the kiln walls. Finally, the irradiance on the kiln walls with and without the particle bed was estimated.

Thermal Behavior and Heat-Flux Distribution in a Solar Rotary Kiln

Isothermal and non-isothermal kinetics of metal oxide redox reactions performed in a solar furnace

Elisa Alonso and Carlos Pérez-Rábago

Abstract

Kinetic behavior of solar processes should be studied in solar facilities in order to consider the real heating conditions that affect the process. In this work, the thermo-desorption of CuO was performed in a solar reactor operated in a solar furnace. Kinetic of this process was studied considering both isothermal and non-isothermal methods. By means of isothermal methods, it was found that the reaction follows the Avrami-Erofeev equation and the kinetic parameters varied according to the n coefficient of such an equation. Master-plots method was then applied from non-isothermal experiments. The employed methodology was easier and the experimentation time much shorter than in isothermal case. The Avrami-Erofeev mechanism was clearly confirmed with this method.

Isothermal and non-isothermal kinetics of metal oxide redox reactions performed in a solar furnace

Potential of solar central tower systems for thermal applications in the production chain of copper by pyrometallurgical route

Irving Cruz-Robles, Alfonso J. Vázquez Vaamonde, Elisa Alonso, Carlos A. Pérez-Rábago, Claudio A. Estrada

Abstract

Copper is an indispensable input element in most economic sectors. However, its production chain has significant and adverse consequences on the environment. Through pyrometallurgical route it is estimated that each kilogram of refined copper consumes 33 MJ and generates a footprint of 3.3 kg of CO2. Primary production projections for 2019 amount to 26,500 kT, of which 79% will be by pyrometallurgical route. It is a responsibility of the industry to makes the process more environmental friendly. This can be done replacing the current energy matrix by the use of renewable energy. In this first and preliminary work we are evaluating the technical potential to integrate Central Tower Plants (CTP) into the smelting stage as a solar energy source. According to the mineral books and the irradiation maps, almost 20% of the current production can be match with these solar concentration systems because of the irradiance levels available where the metallurgical plants are located. The incorporation of a CTP in the world largest copper metallurgical facility to substitute the current fossil fuel energy supply could demand a capacity of 68 MWt. This last consideration obeys to the weighted average of the specific energy consumption gave by the Chilean Copper Commission COCHILCO. However, the results of this work indicate that the behavior of this change in the operative parameters could reduce the 68 MWt almost in a half.

Numerical approach to the flux distribution effect on a solar rotary kiln performance

Alessandro Gallo, Elisa Alonso, Ricardo Pérez-Enciso, Edward Fuentealba, and Carlos Pérez-Rábago

Abstract

New investigations on solar thermochemical storage and other high temperature process are starting at the University of Antofagasta. A small cavity-type solar rotary reactor will be constructed to develop gas-solid reactions. For this reactor concept, is expected that the most part of the solid reactants will remain in the central sector of the drum. Thus, high temperatures at this area will benefit the process performance. Since the radiation profile feeding the solar reactor could have a significant effect on the temperature distribution, in this work it is presented a numerical model to analyze how the use of different concentrators affects the cavity walls temperature. First, a reference case was simulated with flat profile radiation. Then, a solar simulator composed of an elliptical mirror and a high power lamp and a multi-faceted concentrator were considered for the analysis. Their radiation profiles were obtained by ray tracing simulations and integrated in a CFD model that predicts the cavity temperature. It was found a relation between the flux profile and the temperature distribution. This way, higher temperatures were achieved at the back side of the cavity, where the most part of the radiation impinged. The most homogeneous temperature distribution was achieved for the multi-faceted concentrator case, in which lower differences between the back and the lateral wall were found.

Numerical approach to the flux distribution effect on a solar rotary kiln performance

Evaluation of two reflective Coatings for the Mirrors of The High Radiative-Flux Solar Furnace

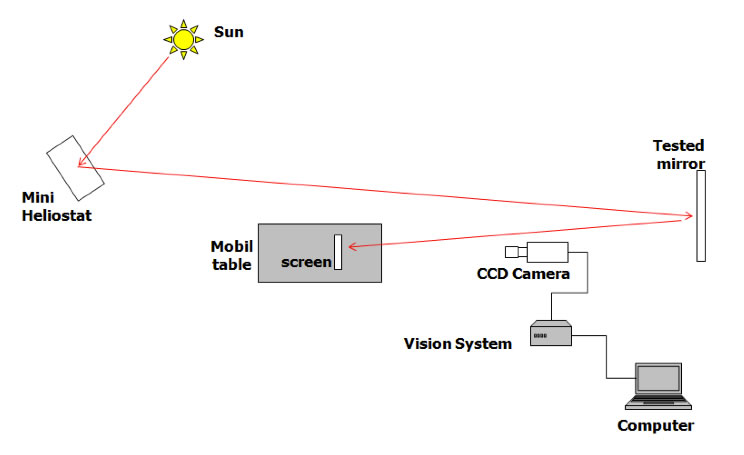

Abstract

We present the initial results for the comparative study of two types of reflecting surfaces for solar concentrating systems. We use two identical mirrors with different coatings: The first have an aluminium coating with SIO2 protection and the second was covered with the commercial film Reflectech®. This cover is used mainly for parabolic trough and has several advantages like a high reflectivity, low maintenance, and resistance to extreme weather conditions. Since this film was developed for concentrating solar applications, the purpose of this study is exploring the potential application of the film in point focus concentrating systems.

Evaluation of two reflective Coatings for the Mirrors of The High Radiative-Flux Solar Furnace

Riveros-Rosas, R. Castrejón-García, C.A. Arancibia-Bulnes, C.A. Pérez-Rábago, C.A. Estrada

Mini-Solar Furnace by Using a Point Focus Solar Concentrator

Abstract

The paper presents the technical modifications of DEFRAC (Spanish acronym for Device for the Study of Highly Concentrated Radiative Fluxes) in order to obtain a mini-solar furnace (MSF). DEFRAC is placed in vertical position and the optical arrangement of facets is oriented viewing to the north. A small flat heliostat system with 5.6 m2 of surface area was designed and constructed to track the movement of the sun and redirect sunlight along to the optical axis of the fixed DEFRAC the concentrator. The reflective surface of the heliostat is obtained by using a flat mirror with a tolerance lesser than 1 mrad. The MSF has a shutter with an area of 2.56 m2 that attenuates the solar energy reflected by the heliostat. In this paper we present the preliminary result of the optical performance for the MSF and the evaluation of the track system of the heliostat and the control of the shutter. The MSF will be used in the development of different kind of studies; from studies of heat transfer in open small cavities to the development of small receivers.

Mini-Solar Furnace by Using a Point Focus Solar Concentrator

Pérez-Rábago C.A., D. Riverso-Rosas, O.A. Jaramillo, M. Bazán, M. Carrillo-Santana, M. Montiel-González, G. Ascanio, C.A. Estrada

Concentration Image Profiles of the High-Flux Solar Furnace of CIE-UNAM in Temixco, Mexico. First Stage

Abstract

In the present work, the analysis of the first images obtained from de Solar Furnace of High Radiative Flux in Mexico is presented. The solar furnace has five different focal distance groups. The images were acquired using the first two groups of mirrors from complete optics of main concentrator. We used a Heliostat with a reflective surface of 36 m². The Images was captured with a CCD camera and the irradiance profile was modeled with a ray-tracing program in order to estimate the global optical error for the concentrator-heliostat optical system. The results shows that the optical error is less to 3 mrad and the calculations indicates that the flux peak for the complete groups of mirrors could be higher than 12 000 suns and the average flux could be higher than 5,000 suns.

David Riveros-Rosas, Carlos A. Perez-Rabago, Camilo A. Arancibia-Bulnes, Ricardo Perez-Enciso, and Claudio A. Estrada

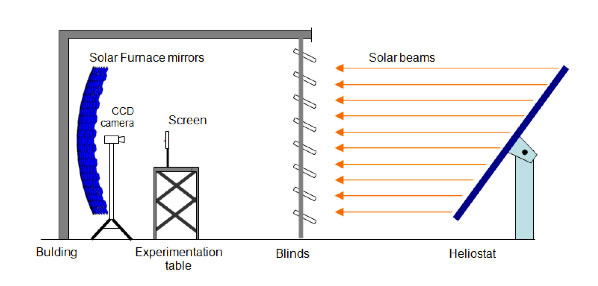

A New High-Flux Solar Furnace at CIE-UNAM in Temixco, México. First Stage

Abstract

A new high flux solar furnace facility has been developed in Mexico. It is located in Temixco, Morelos, Mexico and in its first phase of development consists of a heliostat of 36 square meters (6 m by 6 m), a shutter made of stainless steel blades 6.2 m by 6.2 m, and a multifaceted concentrator of 211 spherical mirrors with an equivalent focal length of 3.64 m. In order to set the HFSF in operation, all the mirrors were aligned, the control system was developed and tested, the heliostat was aligned and its tracking movement tested. The purpose of this paper is to present the new facility and its first results in the evaluation of its capacities. The results show that the optical error is less to 3 mrad and the calculations indicates that the average flux could be higher than 5,000 suns and the facility can reach temperatures as high as 3406º C.

A New High-Flux Solar Furnace at CIE-UNAM in Temixco, México. First Stage

Claudio A. Estrada, Camilo A. Arancibia-Bulnes, Sergio Vazquez, Carlos A. Pérez-Rábago, David Riveros, Ricardo Perez-Enciso, Jesús Quiñones, Rafael Castrejón, Moises Montiel, Fermín Granados

Method for Facets’ Alignment for the High-Flux Solar Furnace at CIE-UNAM in Temixco, Mexico. First Stag

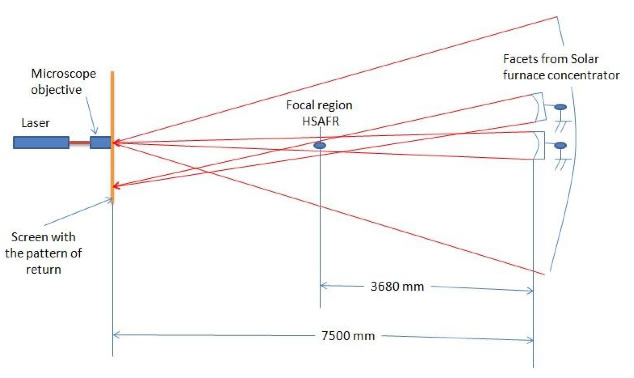

Abstract

The new high radiative flux solar furnace is being developed in Mexico at the Centro de Investigación en Energía of the Universidad Nacional Autónoma de México. The alignment of the facets of the concentrator is a key procedure to obtain the required energy distribution in the focal zone and to keep the global standard deviation of the optical errors low. We present a novel method for optical alignment of the facets; this alignment procedure requires a simple optical system, allows rapid alignment and guarantees the required accuracy. Preliminary results obtained with this procedure are discussed, which show that the facets alignment satisfactorily meets specifications.

S. Vazquez-Montiel, C.A. Pérez-Rábago, R. Pérez-Enciso, D. Riveros-Rosas, F. Granados-Agustin, C.A. Arancibia-Bulnes, C.A. Estrada